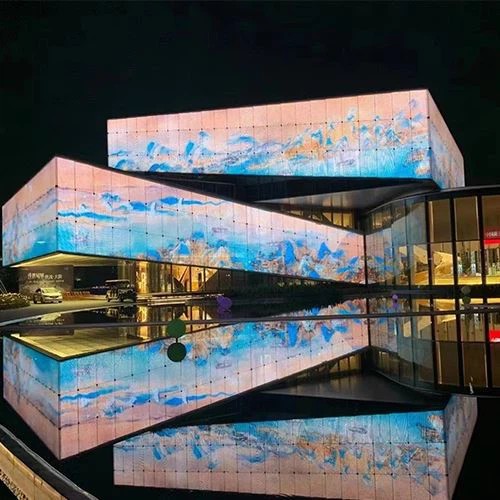

Do you often see those cool glass curtain wall advertisements? Obviously, the entire wall is full of transparent glass, why does it suddenly jump out of the moving underwater world or car advertisement? I tell you, these things that look like magic are hidden behind them. But the question is - where are these factories? Why are some quotes so expensive, while others are so cheap that they doubt their lives?

1. The way to transparent screens

Let me talk about a cold knowledge first: 80% of the world's transparent screen production capacity is concentrated in the Pearl River Delta, especially in Shenzhen, a palm-sized place. Last year's industry report showed that Bao'an District alone gathered more than 200 related companies, from chip packaging to complete machine assembly, driving in half an hour can run a complete industrial chain.

Why are they all gathered here? Three key points:

- Materials Supply Chain: The straight line distance between the glass substrate manufacturer and the driver chip warehouse shall not exceed 5 kilometers

- Technical workers pool: Engineers with more than 10 years of experience have a density of 3 times that of other areas

- Logistics Network: Accessories ordered in the morning can be delivered to the assembly workshop in the afternoon

However, these factories will not mark "transparent screen production base" on Baidu map. They are often hidden in industrial parks, and the door number may say "XX Optoelectronics Technology" or "XX Display Equipment". You can't touch the north without an acquaintance.

2. Three life gates to choose a factory

Last month, I accompanied my friend to conduct a field visit and went to more than a dozen factories to summarize these tricks:

1. Watch the workshop's "light show"

A truly capable factory, the test workshop is brighter at night than during the day. Why? Because I have to do it 72-hour aging test, those flickering screens are actually simulating extreme environments:

- The temperature soared from -20℃ to 60℃

- Humidity remains at 95%RH

- Voltage fluctuates intentionally ±15%

If you see that the entire row of screens simultaneously play 4K videos without color difference, this factory is basically reliable.

2. Touch the thickness of the sample holder

There was a boss's sample room that shocked me - there were three walls with different models of defective products, from the first generation of 2015 to the latest Micro LED transparent screen. This kind of daring to present black history means strict quality control.

Remember this formula:

Qualified factory = (monthly production capacity ÷ sample defect number) >10000

For example, in a factory with a monthly output of 10,000 square meters, there should be about 100 defect samples on the sample holder. If there is nothing clean, you should be wary of whether it is an OEM factory.

3. Listen to the rhythm of the machine

When you walk into the production workshop, don’t look with your eyes and prick up your ears and listen:

- "时-时-时" is the chip machine grabbing the chip

- "Hom——"Changming is the vacuum coating machine working

- The regular "click" sound is an automatic screw locking device

If you hear the alarm sounds one after another, don't panic - this means that the AOI optical detector is working. On the contrary, the workshop that is too quiet is likely to be manual operation.

3. Word game in parameters

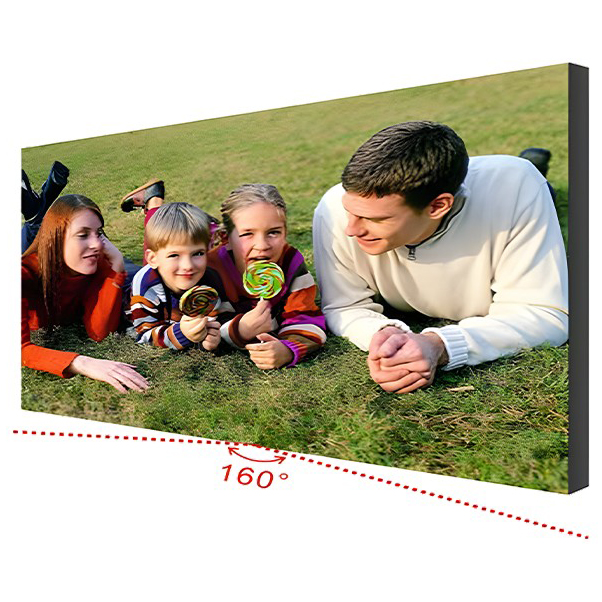

Many manufacturers talk about "transparency rate of 86%", but there are many tricks here:

| parameter | Industry fuss | Cracking method |

|---|

| Transparency | Use naked screen test value to impersonate the installation value | Requires viewing the actual test video after the framework is installed |

| Brightness adjustment | Mark the highest value but not the lowest attenuation | Confirm whether the grayscale is lost at 800cd/m² |

| Protection level | Static test pass ≠ dynamic waterproofing | Requires demonstration operation in spray state |

| Color consistency | Use the mockup after color calibration to fool people | Randomly select three screens to compare |

Last month, a factory demonstrated a ruthless task to us - soaking the screen where the video is playing directly into the fish tank, and displaying it while bubbles appear. This intuitive test is more effective than any certification.

4. The Golden Triangle Area of the Site Selection

Now let me tell you the rules of the crowded factories:

1. Shenzhen Bao'an District

- Advantages: Find all accessories within 20 minutes' drive

- Shortcoming: The factory is dispersed due to land shortage

- Suitable for: projects that are in a hurry to catch up with the construction period

2. Songshan Lake, Dongguan

- Advantages: There is a ready-made glass deep processing industry chain

- Shortcoming: Transportation costs are 15% higher than Shenzhen

- Suitable for: Customized screens that require special shapes

3. Huizhou Zhongkai

- Advantages: Factory rent is 30% cheaper

- Shortcoming: Technical workers need to be dispatched from Shenzhen

- Suitable for: Small and medium-sized projects with limited budget

There is a secret to site selection that people in the industry know: follow the glass freight line. In those industrial parks where container trucks are still running late at night, there are transparent screen production lines hidden.

5. What will the factory look like in the future

I've discovered a new trend recently—— Underground factory. It's not illegal, it means building a dust-free workshop on the underground floor:

- Constant temperature and humidity without air conditioning

- Dust protection effect is increased by 60%

- Equipment vibration reduction by 80%

A factory I visited last week was even more amazing. I directly installed the assembly line on the shockproof platform, saying it was for the purpose ofAerospace-grade screen. Although I don't know whether it is true or not, it looks tall and outstanding.

What is the most subversive cognition is that more and more factories are starting to playTransparent production. Customers can view the production progress of their own batches in real time through mobile APP, and broadcast the entire process from patches to aging tests. Although this gameplay increases management costs by 20%, the order complaint rate has dropped to zero directly.

So, finding a transparent screen factory is like falling in love. Just looking at the appearance is useless, you have to go deep into the production line to find out the details. Next time you want to customize the screen, do you know which direction to dig for treasure?