What are the most feared by newbies who are new to LED screens? It’s not that I can’t install it, but that I just shake my hand and scrap it when I disassemble it! I have seen too many cases of blood and tears - some people pry the frame and tear the circuit board, some people remove the wires without power off, and some people scream when they are powered off, and some people can't get back after disassembly and install them, so they can only be sold as scrap iron. Today we will talk about something real and teach you the secrets of safe screen disassembly.

Sprinkle cold water first: 70% of LED screens on the market have never considered repair needs. Those sealed with glue and screws hidden under the sticker are clearly what you want to get rid of after disassembly. But don’t panic, after reading this article, you can become a "veteran driver for disassembling screens"!

1. Preparation before dismantling is more important than doing it

Don't rush to get the screwdriver! Let’s understand these three things first:

- Check the model label: Usually, on the back or side of the screen, record the pixel spacing (such as P3), power and other parameters, so that it is convenient to match accessories during maintenance.

- Take panoramic photos: Each screw hole position and cable direction must be photographed clearly, so you can save half an hour to avoid blind time when installing it back

- Prepare a complete tool kit: In addition to conventional screwdrivers, you also need to prepare plastic spudger (metal can scratch the frame), anti-static bracelet (especially in winter), and suction cup (it is very easy to use for large-size screens)

Let me give you a real story: Last year, a gym dismantled the floor tiles on the dance floor, but there was no anti-static treatment. As a result, the driver IC was burned as soon as you touch it, and the repair cost was 8,000 yuan more! So, do a good job in preparation and have no worries about the wallet.

2. Five steps to disassemble the machine and walk as steadily as an old dog

In this order, novices can be very stable:

1. Turn off the power and let it sit for 30 minutes

Don't think that just turning off the power supply is done! The electricity stored in the capacitor is enough to make you feel good enough. Some users reported that there was no discharge when disassembling a certain brand of screen, and sparks appeared when the screwdriver hit the interface, and the driver board was directly scrapped.

2. Talent to uninstall the frame

Find the hidden screws first:

- Screws may be hidden under the brand logo sticker

- Use your nails to scratch the seams of the borders. If there is a depression, it may be a snap position.

- Start from the bottom edge with a plastic spudger, and then slowly move when you hear the "click" sound.

3. Cable removal of life and death lines

Remember this mantra: "Sign up first and then power supply, pull up gently and shake slowly." Key points:

- HDMI cable has locks, press and hold the clip before pulling it out

- Mark the power cord (color tape can be used for numbering)

- When encountering a fixed glue cable, use a hot air gun to blow 60℃ for 10 seconds before removing it.

4. Use clever force to disassemble the module

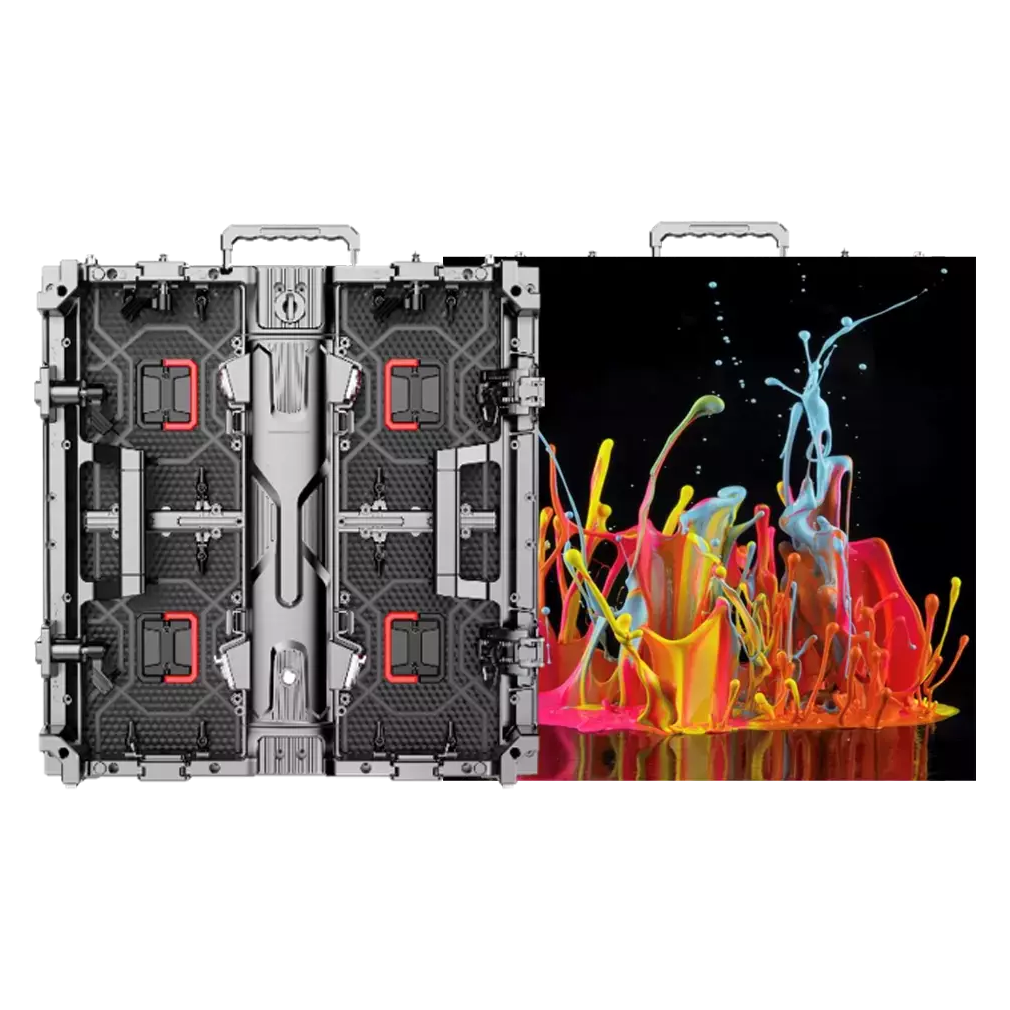

When encountering a rental screen with a box structure (such as quickly disassembling and assembling an aluminum magnesium zinc box), remember three points:

- Remove the upper and lower positioning pins first, and then remove the surrounding screws

- Hold the bottom of the box with both hands and remove it

- Separate it with pearl cotton when stacking to prevent scratching of the mask

5. The motherboard should be gentle when separating

Don't be excited to see the motherboard! Do these two things first:

- Tear off the heat dissipation silicone pad (excessive force will cause the solder joint to be broken)

- Use the macro mode of the mobile phone to take a picture of the chip model (convenient for later maintenance)

3. Don't step on these pitfalls

Experience gained from blood and tears:

- Don't pry the IP65 protective screen hard: The sealant strip should be soaked with degreasing agent. If it is tear directly, it will deform and leak water.

- Removing the mask with transparent screen: The screen surface with a 86% permeability has a nanocoated coating, and the fingerprints cannot be erased

- Stadium fence screen pays attention to structure: The IP65 protection clamp design is special, and the wrong order will break the clamping teeth

- The most important thing about anti-static floor tiles screens: The dance floor screen is often rubbed by the sole, so be sure to connect the grounding wire before disassembly

I heard that a hot pot restaurant owner disassembled the advertising screen by himself, but the waterproof rubber ring was installed in the reverse direction, and it turned into a "water curtain cave" in the rainy season. So, it is more reliable to leave professional matters to a 24-hour response technical team [providing full-life cycle technical support].

4. Choose the right tool and get twice the result with half the effort

Don't underestimate the selection of tools, there are many tricks here:

- The screwdriver must be magnetic: Prevent the screw from falling into the gap in the screen (don't ask how to know)

- Three sizes of spudger: Large size remove the border, medium size cable, small size clip buckle

- Multimeter voltage measurement: The voltage at key points must be measured before and after disassembly to prevent leakage

- A must-have mobile phone stand: Record the entire video, and you can watch it as a tutorial when you install it back

Cold knowledge: A truly reliable manufacturer will make color marks at the screw holes, such as red represents load-bearing screws, and blue is auxiliary fixing. There will be no errors when disassembling.

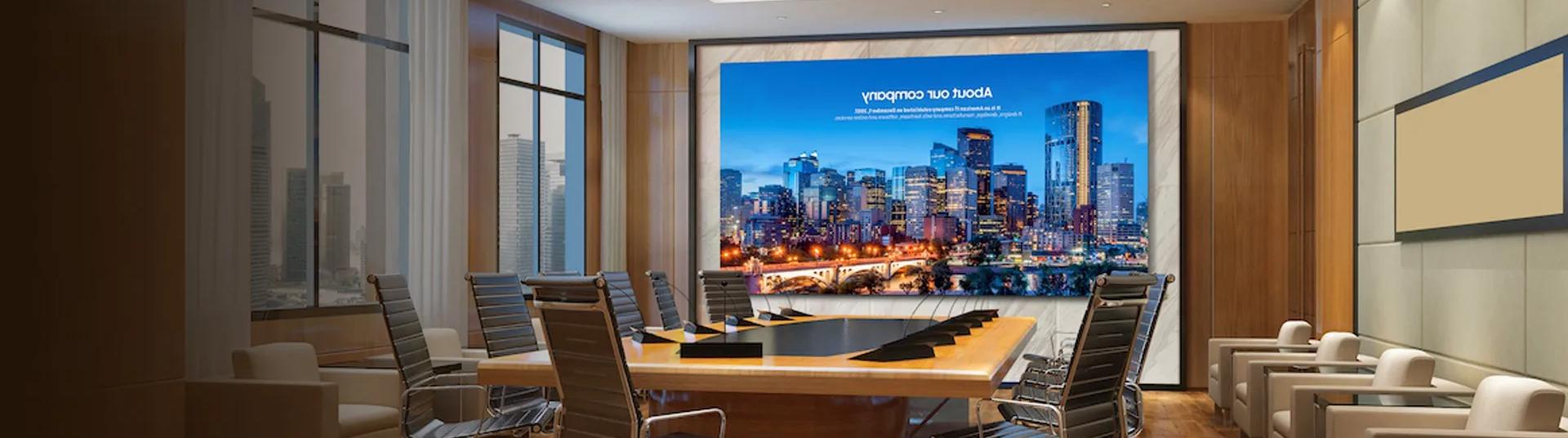

Editor's opinion

It’s like dismantling the LED screen, it’s like having surgery. I think it’s simple when I watch the video, but I only know how difficult it is if I really get started. Especially those P4 curved screens used in smart city projects, the disassembly and assembly accuracy requires thinner than hair. I suggest that you don’t remove it yourself during the warranty period. A manufacturer with 24-hour technical support [setting up a 24-hour technical response center] will call the engineer and come to the door with professional tools. Why save a small amount of money and take big risks? Remember, knowing how to dismantle is not a skill, and it is only real skill that can be used for ten years after dismantle!